Bobcat Loader 600 600D 610 611 Service Manual 6556276

Original price was: 40 $.30 $Current price is: 30 $.

- Brand: Bobcat

- Model: Loader 600 600D 610 611

- Type Of Manual: Service Manual

- Manual ID: 6556276

- Format: PDF

- Size: 4.4MB

- NumPage: 216

Description

MAINTENANCE SAFETY

CONTENTS

– FOREWORD

GENERAL SERVICE

– SERVICE SCHEDULE

– TIRES

– LOADER LUBRICATION

– CHANGING AND ADDING HYDRAULIC OIL

– REMOVING WATER FROM HYDRAULIC TANKS

– BOBTACH FRAME

– HYDRAULIC FLUID FILTERCHANGE

– ENGINE AIR CLEANER

– OIL TYPE AIR CLEANER

– HEAVY DUTY AIR CLEANER

– ENGINE OIL

– OIL SPECIFICATIONS FOR ENGINES

– ENGINE OIL FILTER Wisconsin

– ENGINE OIL FILTER Duetz Diesel

– OIL FILTER Petter

– CRANKCASE AIR VENT Wisconsin

– CRANKCASE AIR VENT Deutz

– FUEL SPECIFICATIONS

– FUEL FILTER

– EXCESS FUEL LEVER ADJUSTMENT Deutz Engine

– FUEL PUMP Wisconsin

– FUEL ADJUSTMENT Petter

– ENGINE COOLING SYSTEM

– WATER SCRUBBER MUFFLER 600 Diesel

– IGNITION TIMING Wisconsin Engine

– DISTRIBUTOR MAINTENANCE Wisconsin

– SPARK PLUG Wisconsin

– ELECTRICAL SYSTEMS

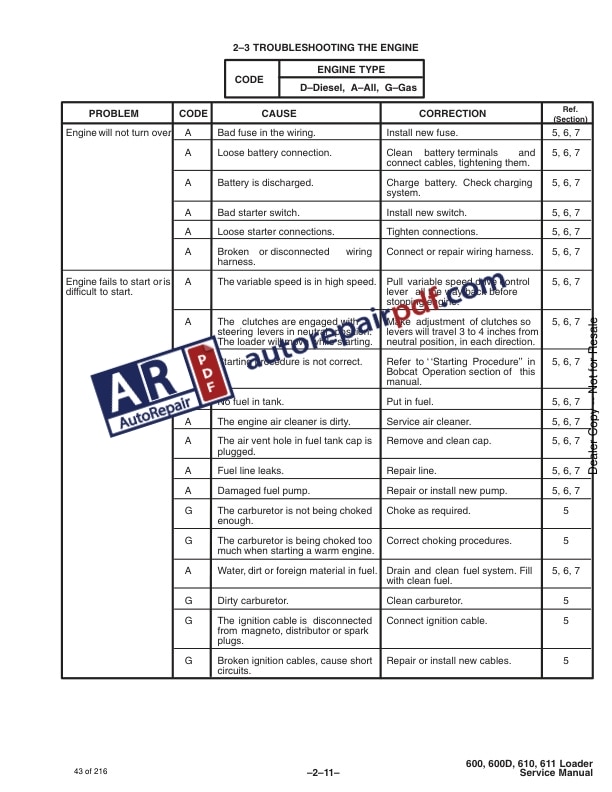

TROUBLESHOOTING

– TROUBLESHOOTING THE DRIVE SYSTEM

– TROUBLESHOOTING THE HYDRAULIC SYSTEM

– TROUBLESHOOTING THE ENGINE

DRIVE SYSTEM

– CLUTCH ADJUSTMENT

– DISASSEMBLY ASSEMBLY

– INSTALLING CLUTCH NEEDLE BEARINGS.

– DRIVE BELT INSTALLATION Split Shaft

– REMOVAL OF DRIVEN SHEAVE

– INSTALLING OF DRIVEN SHEAVE

– DRIVEN SHEAVE DISASSEMBLY

– ASSEMBLY OF DRIVEN SHEAVE TAPERED JACKSHAFT

– DISASSEMBLY OF DRIVE SHEAVE STRAIGHT JACKSHAFT

– ASSEMBLY OF DRIVEN SHEAVE STRAIGHT JACKSHAFT

– DRIVEN SHEAVE ALIGNMENT

– JACKSHAFT BEARING INSTALLATION

– REMOVAL OF VARIABLE DRIVE SHEAVE WITH ROTO SWIVEL INSIDE 600, 610 Gasoline and Diesel, Serial Number 72319 and Up

– ROTOSWIVEL DISASSEMBLY

– ROTOSWIVEL ASSEMBLY

– ASSEMBLY PROCEDURES FOR 610 VARIABLE SPEED WITH ROTOSWIVEL INSIDE

– REMOVAL OF VARIABLE SHEAVE WITH ROTOSWIVEL OUTSIDE 600 Gasoline, LP and Diesel Serial Number 6725372318

– REMOVAL OF FRAME SUPPORT VARIABLE SHEAVE 600 Gasoline and LP serial Number 6279667252

– AXLE REMOVAL FRONT AXLE

– AXLE BEARING AND SEAL INSTALLATION

– INSTALLATION OF AXLE

– AXLE SPROCKET REMOVAL INSTALLATION

– LOWER JACKSHAFT REMOVAL

– LOWER JACKSHAFT SPROCKET REPAIR

– LOWER JACKSHAFT INSTALLATION

– DRIVE CHAIN ADJUSTMENT

– BRAKE ASSEMBLY

– ASSEMBLY OF BRAKE

– BRAKE ADJUSTMENT

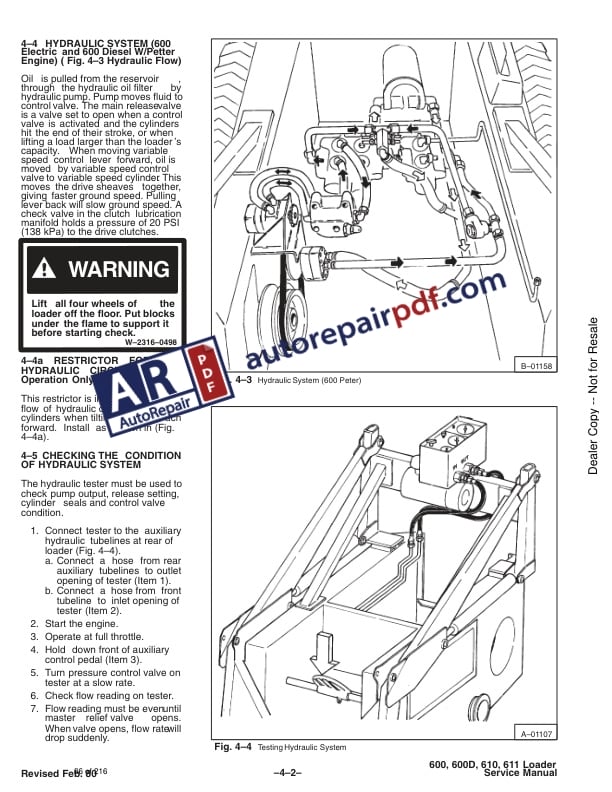

HYDRAULIC SYSTEM

– HYDRAULIC SYSTEM

– RESTRICTOR FOR TILT HYDRAULIC CIRCUIT Grapple Operation Only

– CHECKING THE CONDITION OF HYDRAULIC SYSTEM

– RECOMMENDED HYDRAULIC OILFLOW RATE

– CHECKING CONDITION OF HYDRAULIC PUMP

– CHECKING THE PRESSURE SETTING OF THE CARTRIDGE RELEASE In Lift and Auxiliary Control Valve

– MASTER RELEASE VALVE ADJUSTMENT

– CARTRIDGE RELEASE ADJUSTMENT

– CHECKING VARIABLE SPEED VALVE PRESSURE ADJUSTMENT Variable Speed Swivel Couplings

– CHECKING PRESSURE ADJUSTMENT Variable Speed Control Valve with no Holding Pressure Valve

– VARIABLE SPEED CLOSING PRESSURE ADJUSTMENT Variable Speed Control Valve with or with no Holding Release Valve

– VARIABLE SPEED HOLDING RELEASE PRESSURE SETTING 600 PSI 4137 kPa Minimum

– DISASSEMBLY OF VARIABLE SPEED CONTROL VALVE Seal Replacement with Control Valve in the Bobcat

– ASSEMBLY OF VARIABLE SPEED CONTROL VALVE, SEAL REPLACEMENT WITH CONTROL VALVE IN THE BOBCAT With Holding Release Valve

– CONTROL VALVE SEAL INSTALLATION

– INSTALLING VALVE SPOOL SEALS IN THE VARIABLE SPEED CONTROL VALVE

– HYDRAULIC PUMP SERVICE Webster Pump

– DISASSEMBLY

– ASSEMBLY OF HYDRAULIC PUMP Webster Pump

– HYDRAULIC PUMP DISASSEMBLY Cessna Pump

– HYDRAULIC PUMP ASSEMBLY Cessna Pump

– HYDRAULIC LIFT OR TILT CYLINDER DISASSEMBLY

– INSTALLATION OF CYLINDER SEALS

– HYDRAULIC CYLINDER ASSEMBLY

– HYDRAULIC PUMP ALIGNMENT 500 ELECTRIC

– HYDRAULIC PUMP ALIGNMENT 600 Wisconsin

WISCONSIN ENGINE SERVICE

– RETURN OF NORMAL COMPRESSION

– GOVERNOR ADJUSTMENT

– STORAGE OF ENGINE

– RETURN STORED ENGINE TO SERVICE

– CARBURETOR ADJUSTMENT

– CARBURETOR RECONDITIONING

– TO DISASSEMBLE THROTTLE BODY

– DISASSEMBLY OF THE FUEL BOWL

– O ASSEMBLE FUEL BOWL AND INTAKE ASSEMBLY

– TO ASSEMBLE THROTTLE BODY

– ASSEMBLY OF FUEL BOWL AND THROTTLE BODY

– LP CARBURETOR SERVICE

– CARBURETOR REMOVAL

– LP CARBURETOR RECONDITIONING

– DISASSEMBLY PROCEDURE LP CARBURETOR

– CLEANING AND INSPECTION

– ASSEMBLE LP CARBURETOR

– VAPORIZER PRIMARY REGULATOR SERVICE

– DISASSEMBLING THE VAPORIZER

– TO ASSEMBLE THE VAPORIZER

– ADJUSTMENT OF VAPORIZER

– LP FUEL FILTER LOCKOFF

– FUEL FILTER LOCKOFF DISASSEMBLY

– ENGINE RECONDITIONING

– REMOVAL OF ENGINE

– REMOVAL OF ACCESSORIES

– REMOVAL OF FLYWHEEL

– REMOVAL OF AIR HOUSING

– REMOVAL OF CARBURETOR AND MANIFOLD

– REMOVAL OF CYLINDER HEAD

– REMOVAL OF GEAR COVER

– REMOVAL OF CAMSHAFT

– REMOVAL OF IDLER GEARAND SHAFT

– REMOVAL OF OIL PAN

– REMOVAL OF OIL PUMP

– REMOVAL OF PISTONS AND CONNECTING RODS

– REMOVAL OF VALVES AND SEAT INSERTS

– REMOVAL OF CYLINDER BLOCK

– REMOVAL OF CRANKSHAFT

– REMOVAL OF CAMSHAFT

– REMOVAL OF VALVE TAPPET

– ASSEMBLY OF ENGINE AFTER RECONDITIONING INSTALLATION OF VALVE TAPPETS

– INSTALLATION OF CAMSHAFT

– INSTALLATION OF CRANKSHAFT

– INSTALLATION OF VALVES AND SEAT INSERTS

– INSTALLATION OF CYLINDER BLOCKS

– INSTALLATION OF PISTON RINGS

– INSTALLATION OF PISTONS AND CONNECTING RODS

– INSTALLATION OF OIL PUMP

– OIL PAN INSTALLATION

– INSTALLATION OF IDLER GEAR AND SHAFT

– INSTALLATION OF CAMSHAFT GEAR

– INSTALLATION OF GEAR COVER

– INSTALLATION OF CYLINDER HEAD

– INSTALLATION OF CARBURETOR AND MANIFOLD ASSEMBLY

– INSTALLATION OF AIR HOUSING

– INSTALLATION OF FLYWHEEL

– INSTALLATION OF ACCESSORIES

DEUTZ ENGINE SERVICE

– INSTRUCTIONS FOR TIGHTENING BOLTS AND STUDS

– CHECK AND ADJUSTMENTS

– ENGINE RECONDITIONING

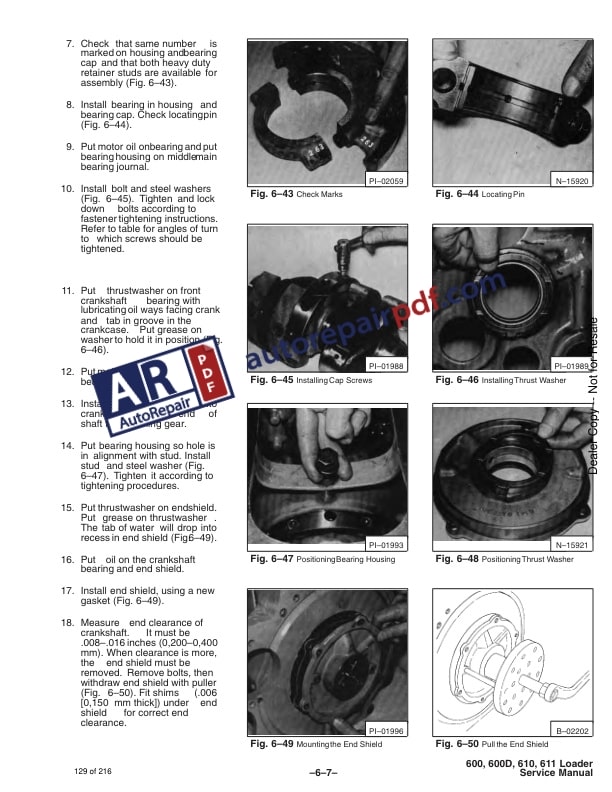

– TO ASSEMBLE THE ENGINE

– INSPECTION AND REPAIR

– GENERAL ENGINE DATA F2L410

– FITS, CLEARANCES, ADJUSTMENTS DEUTZ ENGINE

– SPECIAL TOOLS

PETTER ENGINE SERVICE

– ENGINE DISASSEMBLY AND REPAIR

– TECHNICAL DATA Fits, Clearances Torques

SPECIFICATIONS

– ENGINE SPECIFICATIONS WISCONSIN

– ENGINE SPECIFICATIONS DEUTZ

– ENGINE SPECIFICATIONS PETTER

– MOTOR SPECIFICATIONS, ELECTRIC

– TECHNICAL DATA

ALPHABETICAL INDEX

SERVICE BULLETINS

SERVICE MANUAL REVISIONS

– 600002

– 600003

– 600004

Reviews

There are no reviews yet.