Bobcat Utility Vehicle 2100 2100S Service Manual 6901987

Original price was: 40 $.30 $Current price is: 30 $.

- Brand: Bobcat

- Model: Utility Vehicle 2100 2100S

- Type Of Manual: Service Manual

- Manual ID: 6901987

- Format: PDF

- Size: 13.4MB

- NumPage: 382

Description

Section 1 Safety

General Warning

Section 2 Vehicle Specifications

Section 3 General Information

General Information

Serial Number Identification

Storage

– Preparing the Vehicle for Extended Storage

– To Return Vehicle to Service

Section 4 Body and Trim

Cleaning the Vehicle

Front Body Repair

– Abrasions and Haze

– Light Scratches

– Large Scratches and Abrasions

Front Body Components

– Dashboard Removal

– Dashboard Installation

– Front Body Removal

– Front Fender Removal

– Front Fender Installation

– Front Body Installation

Seat

– Seat Adjustment

Front Seat Support

– Front Seat Support Removal

– Front Seat Support Installation

Rear Seat Support

– Rear Seat Support Removal

– Rear Seat Support Installation

Cargo Bed

– Cargo Bed Removal

– Cargo Bed Installation

– Bed Stop Bumper Adjustment

Rear Fender

– Rear Fender Removal

– Rear Fender Installation

Tailskirt

– Tailskirt Removal

– Tailskirt Installation

Receiver Hitch

– Receiver Hitch Removal

– Receiver Hitch Installation

Floor Mat

– Floor Mat Removal

– Floor Mat Installation

Section 5 Accelerator and Brake Pedal Assemblies

Brake Pedal

– Brake Pedal Removal

– Brake Pedal Installation

Brake Pedal Adjustment

Accelerator Pedal

– Accelerator Pedal Removal

– Accelerator Pedal Installation

Accelerator Pedal Adjustment

Section 6 MC012CAS00 Transaxle Hydraulic and Park Brake Systems

Brake System Inspection

Brake System Troubleshooting

Brake Drum Removal

– Front Wheel Brake Drum Removal

– Rear Wheel Brake Drum Removal

Brake Shoe Removal

– Front Brake Shoe Removal

– Rear Brake Shoe Removal

Brake Cluster Inspection and Cleaning

Brake Shoe Installation

– Front Brake Shoe Installation

– Rear Brake Shoe Installation

Brake Drum Installation

– Front Wheel Brake Drum Installation

– Rear Wheel Brake Drum Installation

Brake Cluster Assembly Replacement

– Front Brake Cluster Assembly Removal

– Front Brake Cluster Assembly Installation

– Rear Brake Cluster Assembly Removal

– Rear Brake Cluster Assembly Installation

Wheel Cylinder Replacement

– Front Wheel Cylinder Removal

– Front Wheel Cylinder Installation

– Rear Wheel Cylinder Removal

– Rear Wheel Cylinder Installation

Brake Shoe Adjuster Replacement

– Front Brake Shoe Adjuster Removal

– Front Brake Shoe Adjuster Installation

– Rear Brake Shoe Adjuster Removal

– Rear Brake Shoe Adjuster Installation

Hydraulic Line and Hose Replacement

– Front Brake Line Removal

– Front Brake Line Installation

– Front Brake Hose Assembly Removal

– Front Brake Hose Assembly Installation

– Rear Brake Line Removal

– Rear Brake Line Installation

– Rear Brake Hose Removal

– Rear Brake Hose Installation

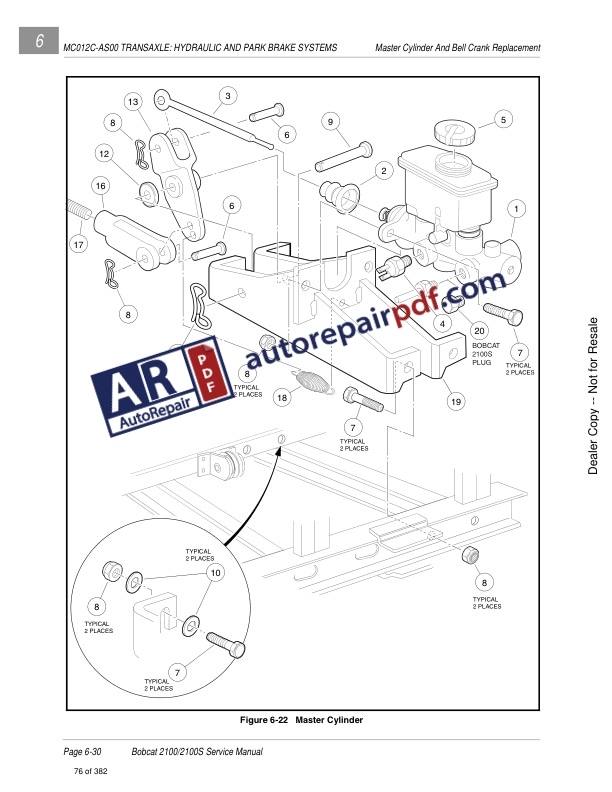

Master Cylinder And Bell Crank Replacement

– Bell Crank Removal

– Bell Crank Installation

– Master Cylinder Removal

– Master Cylinder Installation

Bleeding the Hydraulic Brake System

– Purging the Hydraulic System

– Filling the Hydraulic System

Park Brake System

– Park Brake Cable Removal

– Park Brake Cable Installation

– Park Brake Handle Removal

– Park Brake Handle Installation

– Park Brake Adjustment

Section 7 Steering and Front Suspension

Steering Wheel

– Steering Wheel Removal

– Steering Wheel Installation

Steering Column

– Steering Column Removal

– Steering Column Disassembly

– Steering Column Assembly

– Steering Column Installation

Rack and Pinion

– Rack and Pinion Removal

– Rack and Pinion Disassembly

– Rack and Pinion Assembly

– Rack and Pinion Installation

Front Suspension

– Lubrication

– Wheel Alignment

Front Suspension Components

– Kingpin and Steering Spindle Removal

– Kingpin and Steering Spindle Installation

– AArm Removal

– AArm Installation

– Shock Absorber Removal

– Shock Absorber Installation

Front Wheel Bearings and Hubs

– Front Wheel Free Play Inspection

– Front Wheel Bearings and Hub Removal

– Front Wheel Bearings and Hub Installation

Section 8 Wheels and Tires

General Information

Section 9 Rear Suspension

Shock Absorbers

– Shock Absorber Removal and Inspection

– Shock Absorber Installation

MultiLeaf Springs

– MultiLeaf Spring Removal

– MultiLeaf Spring Installation

Snubber

– Snubber Removal

– Snubber Installation

Section 10 Periodic Maintenance

Periodic Service Schedule

Periodic Lubrication Schedule

Master Cylinder

– Brake Fluid

Engine Oil

– Engine Oil Level Check

– Engine Oil and Filter Change

– Oil Viscosity

Fueling Instructions

Battery

Section 11 Troubleshooting and Electrical System FE400 Engine

Troubleshooting Guide

Electrical System

Wiring Diagram

Electrical Circuits

– Starter Circuit

– Generator Circuit

– Engine Ignition Circuit

– Engine Kill Circuit

– Reverse Buzzer Circuit

– Low Oil Warning Circuit

– Lockout Cam Circuit

– Fuel Gauge and Sending Unit Circuit

– Hour Meter Circuit

– Lighting Circuit

Circuit Testing

– Testing the Starter Circuit and Generator Circuit

– Testing the Engine Ignition Circuit

– Testing the Engine Kill Circuit

– Testing the Reverse Buzzer Circuit

– Testing the Low Oil Warning Circuit

– Testing the Lockout Cam Circuit

– Testing the Fuel Gauge and Sending Unit Circuit

– Testing the Lighting Circuit

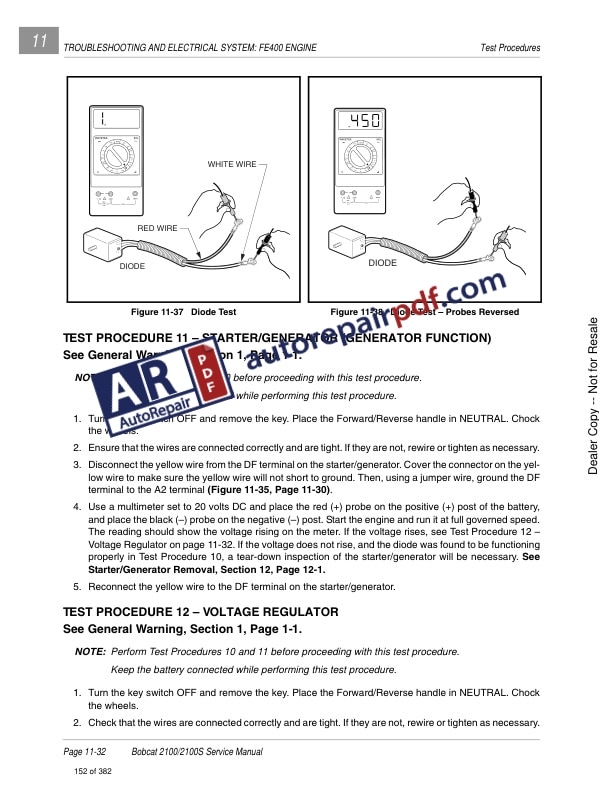

Test Procedures

– Index of Test Procedures

Section 12 Electrical Components FE400 Engine

StarterGenerator

Voltage Regulator

Diode

Key Switch

Solenoid

Fuse

Lockout Cam Limit Switch

Lockout Cam

Reverse Warning Buzzer

Reverse Buzzer Limit Switch

Low Oil Warning Light

Fuel GaugeHour Meter

Fuel Level Sending Unit

RPM Limiter

Ignition Coil

Oil Level Sensor

Headlights

Headlight Diode

Light Switch

– Testing the Light Switch

Battery

– General Information

Ground Straps

Section 13 FE400 Engine

General Information

– Before Servicing

– Lubrication System

– Spark Plug

Cylinder

– Breather Valve Reed Valve

– Valve Clearance Check and Adjustment

Crankcase

– Engine Removal

– Crankcase Cover Removal

– Oil Level Sensor

Ignition Coil and Flywheel

– Crankcase Cover Installation

Flywheel Installation

Engine Installation

– Torque Specifications

– Adjustment and Settings

Section 14 Fuel System

General Information

Carburetor

– Main Jet ElevationSize Chart

– Changing the Main Jet

Engine Control Linkage

– General Information

– Accelerator Rod

– Governor Cable

– Accelerator Cable

– Closed Throttle or Idle Adjustment

– Engine RPM Adjustment

Choke and Air Intake System

– Choke Cable Removal

– Choke Cable Installation

– Air Box Removal

– Air Box Installation

– Intake Duct Repair

– Intake Duct Removal

– Intake Duct Installation

– Air Filter

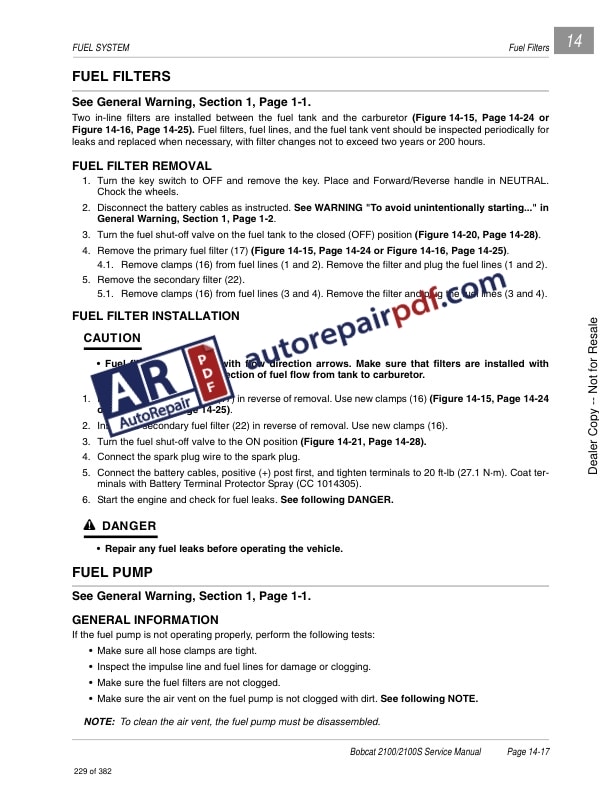

Fuel Filters

– Fuel Filter Removal

– Fuel Filter Installation

Fuel Pump

– General Information

– Fuel Pump Removal

– Fuel Pump Disassembly

– Fuel Pump Cleaning and Inspection

– Fuel Pump Assembly

– Fuel Pump Installation

Fuel Tank

– Fuel Tank Removal

– Fuel Tank Storage or Disposal

– Fuel Tank Installation

Fuel Lines

Fuel ShutOff Valve

Section 15 Exhaust System

Muffler

– Muffler Removal

– Muffler Installation

Section 16 MC012CAS00 Unitized Transaxle with Differential Lock

General Information

– Lubrication

Axle Shaft

– Axle Shaft, Bearing, and Oil Seal Removal

– Axle Bearing Removal

– Axle Shaft, Bearing, and Oil Seal Installation

Unitized Transaxle Removal

Unitized Transaxle Installation

ForwardReverse Shifter Cable

– ForwardReverse Shifter Cable Removal

– ForwardReverse Shifter Cable Installation

– ForwardReverse Shifter Cable Adjustment

Differential Lock System

– Differential Lock System Inspection

– Differential Lock Cable Removal

– Differential Lock Cable Installation

Section 17 Torque Converter

General Information

Troubleshooting

Drive Belt

– Drive Belt Removal

– Drive Belt Installation

Drive Clutch

– Drive Clutch Removal

– Drive Clutch Cleaning and Inspection

– Drive Clutch Disassembly

– Inspection of Drive Clutch Parts

– Drive Clutch Assembly

– Drive Clutch Installation

Driven Clutch

– Driven Clutch Removal

– Driven Clutch Disassembly

– Driven Clutch Inspection

– Driven Clutch Assembly

– Driven Clutch Installation

Section 18 Reconditioning the FE400 Engine

General Information

Special Engine Service Tools Available

– Recommended Replacement Parts For Engine Teardown

– Before Servicing

– Mechanical Systems

Cylinder Components

– Cylinder Head

– General Information

– Cylinder Shroud Removal

– Rocker Arm and Push Rod Removal

– Cylinder Head Removal

– Valve Removal

– Breather Valve Reed Valve

– Cylinder Head Cleaning and Inspection

– Valve Guides

– Valve Seats

– Valves

– Rocker Arm and Rocker Shaft inspection

– Push Rod Inspection

– Cylinder Head Installation

– Valve Clearance Check and Adjustment

– Breather Valve Reed Valve

– Installation of Remaining Engine Components

Crankcase Components

– Crankcase Cover Removal

– Camshaft and Hydraulic Lifters

Piston and Connecting Rod

Cylinder Block

Ignition Coil and Flywheel

Oil Pump

– Oil Pressure Relief Valve

Crankshaft and Counterbalance

– Counterbalance Weight

– Oil Screen

– Ball Bearing

– Oil Seals

Crankshaft Axial Play Adjustment

– Crankcase Cover Installation

Engine Assembly

Engine Installation

Service Specifications

– Specifications for Resizing Cylinder Bore

– Torque Specifications

– Adjustment and Settings

Section 19 Reconditioning the MC012C AS00 Unitized Transaxle with Differential Lock

General Information

Transaxle Model and Identification

– Lubrication

Axle Shaft

Unitized Transaxle Removal

Unitized Transaxle Disassembly

Component Disassembly

– Differential Gear Lock Housing Disassembly

– Governor Gear Disassembly

– Differential Gear Case Disassembly

– Shifter Fork Disassembly

– Synchronizer Gear Disassembly

– Intermediate Gear Disassembly

– Idler Shaft Disassembly

Unitized Transaxle Component Inspection

Component Assembly

– Idler Shaft Assembly

– Intermediate Gear Assembly

– Synchronizer Gear Assembly

– Shifter Fork Assembly

– Differential Gear Case Assembly

– Governor Gear Assembly

– Differential Gear Lock Housing Assembly

Unitized Transaxle Assembly

Unitized Transaxle Installation

Reviews

There are no reviews yet.