Bobcat Loader M970 Service Manual 6545690

Original price was: 40 $.30 $Current price is: 30 $.

- Brand: Bobcat

- Model: Loader M970

- Type Of Manual: Service Manual

- Manual ID: 6545690

- Format: PDF

- Size: 7.7MB

- NumPage: 190

Description

MAINTENANCE SAFETY

FOREWORD

CONTENTS

BOBCAT OPERATION

– INSTRUMENTATION

– ENGINE CONTROLS

– DRIVE CONTROLS

– LOADER CONTROLS

– PRESTART CHECK

– STARTING PROCEDURE

– COLD WEATHER STARTING

– OPERATING THE M970 BOBCAT

– BREAKIN

LOADER SERVICE AND MAINTENANCE

– BOBTACH SYSTEM

– TRANSPORTING THE M970

– TRANSPORTING BY TRUCK OR TRAILER

– HOISTING THE M970

– MAINTENANCE SCHEDULE

– SERVICE SCHEDULE

– TIRE MAINTENANCE

– BELLY PAN

– OPERATOR ENCLOSURE TILT CONTROL

– ENCLOSURE TILT CONTROL SERVICE

– ENCLOSURE REMOVAL AND REINSTALLATION

– ENCLOSURE LATCHES

– CONTROL LEVER LOCK

– LIFT ARM PIVOT REPLACEMENT

– REWORKING THE LIFT ARM ASSEMBLY

– SIDE PANEL FENDER REMOVAL

– GRILL REMOVAL

– FUEL TANK

– FUEL PICKUP TUBE

– ENGINE HOOD

– INTRODUCTION TO ENGINE SERVICE

– INITIAL 50 HOUR SERVICE

– AIR CLEANER SERVICE

– HEAVY DUTY, TWO STAGE, MULTIPLE ELEMENT AIR CLEANER WITH ASPIRATOR

– FIELD SERVICEING THE AIR CLEANER DONALDSON ONLY

– ENGINE LUBRICATION SERVICE

– RECOMMENDED OIL SPECIFICATIONS

– CHANGING ENGINE OIL

– OIL FILTER REPLACEMENT

– FUEL SYSTEM SERVICE

– FUEL SPECIFICATIONS

– VENTING FUEL SYSTEM DIESEL

– INJECTOR SERVICE DIESEL ONLY

– CYLINDER HEAD RETORQUING DIESEL ONLY

– VALVE CLEARANCE ADJUSTMENT DIESEL ONLY

– COOLING SYSTEM SERVICE

– RADIATOR COOLING FANS

– FAN BELT ADJUSTMENT

ELECTRICAL SERVICE

– INSTRUMENT PANELS

– FUSES

– WIRING HARNESS

– ALTRNATOR CHECK

– REGULATOR CHECKS

– YACHOMETER TESTING AND CALIBRATION

– BATTERY INSTALLATION

– BATTERY PROBLEMS

– REPLACING HEADLAMPS

HYDRAULIC AND HYDROSTATIC SERVICE

– BASIC OPERATING PRINCIPLE OF HYDRAULIC SYSTEM

– FILTER SERVICE

– 100 MESH FILTER SCREEN

– HYDRAULIC TESTING KIT

– LIFT AND TILT CYLINDER CHECKS

– HYDRAULIC CYLINDER INSPECTION

– LIFT CYLINDER SERVICE

– TILT CYLINDER SERVICE

– HYDRAULIC CONTROL VALVE BANK REMOVAL

– CONTROL VALVE SERVICE

– DISASSEMBLY INSTRUCTIONS

– SELF LEVELING CONTROL VALVE

– HYDRAULIC PUMP IMPLEMENT CIRCUIT

– HYDRAULIC PUMP REMOVAL

– HYDRAULIC PUMP DISASSEMBLY

– HYDRAULIC PUMP REASSEMBLY

– HYDRAULIC OPERATING PRINCIPLE

– HYDROSTATIC CIRCUITRY

– DIRECTIONAL CONTROL ADJUSTMENT

– CONTROL ASSEMBLY REMOVAL

– PUMP AND MOTOR CONTROL ADJUSTMENT

– HYDROSTATIC CHARGE PUMP

– CHECKING CHARGE PRESSURE

– HYDRAULIC FLUID AND 10 MICRON FILTER

– TRANSMISSION STARTUP PROCEDURE

– CHARGE PUMP REMOVAL

– CHARGE PUMP REINSTALLATION

– CHECK VALVE REMOVAL

– CHECK VALVE REINSTALLATION

– TESTING CHECK VALVES

– HYDROSTATIC PUMP REMOVAL

– PUMP REINSTALLATION

– MOTOR REMOVAL

– MOTOR REINSTALLATION

– PUMP OR MOTOR DISPLACEMENT CONTROL VALVE

– DISPLACEMENT CONTROL VALVE REMOVAL

– DISPLACEMENT CONTROL VALVE REINSTALLATION

– MOTOR MANIFOLD BLOCK

– MANIFOLD BLOCK REMOVAL

– MANIFOLD BLOCK REINSTALLATION

– REMOVAL OF THE SEAL FROM THE PUMP OR MOTOR

– SEAL REINSTALLATION

– HYDRAULIC FLUID COOLER

– COOLER REMOVAL

– COOLER REINSTALLATION

– COOLER BYPASS VALVE

– HYDRAULIC LEAKS

– COST OF OIL LEAKS

– 37 FLARE SAE CONNECTION

– SAE STRAIGHT THREAD ORING SEAL

– SAE 4 BOLT SPLIT FLANGE CONNECTION

– OVERHAUL OF HYDROSTATIC PUMP OR MOTOR

– REMOVAL OF PUMP OR MOTOR FROM VEHICLE

– DISASSEMBLY PROCEDURE

– REMOVING CHARGE PUMP

– REMOVING CHECK VALVES

– REMOVING END CAP

– REMOVING VALVE PLATE

– REMOVING BRASS BEARING PLATE

– REMOVING REAR BEARING

– REMOVING SPRING GUIDE

– REMOVING CYLINDER BLOCK

– REMOVING SLIPPER RETAINER

– REMOVING PISTONS AND SLIPPER RETAINER

– REMOVING THRUST PLATE

– REMOVING FRONT COVER

– REMOVING CONTROL VALVE ASSEMBLY

– REMOVING TRUNNION

– SERVO SLEEVES

– REASSEMBLY PROCEDURE

– SET SHAFT END PLAY

– ASSEMBLING SERVO PISTONS

– ATTACHING SERVO PISTON ASSEMBLIES TO SWASH PLATE

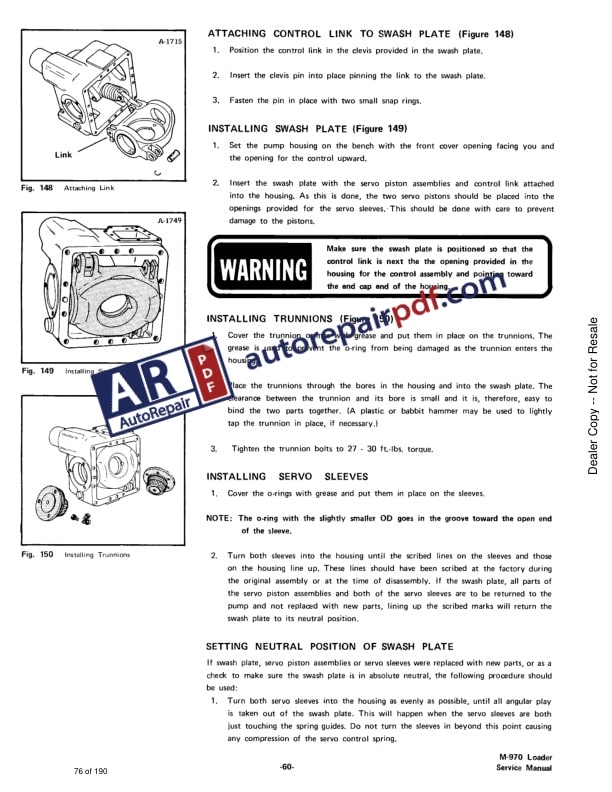

– ATTACHING CONTROL LINK TO SWAH PLATE

– INSTALLING SWASH PLATE

– INSTALLING TRUNNIONS

– INSTALLAING SERVO SLEEVES

– SETTING NEUTRAL POISTION OF SWASH PLATE

– INSTALL THE CONTROL ASSEMBLY

– INSTALLING THE THRUST PLATE

– INSTALLING THE DRIVE SHAFT

– INSTALLING FRONT COVER AND GASKET

– ASSEMBLING THE CYLINDER BLOCK

– ASSEMBLE THE CYLINDER BLOCK ASSEMBLY INTO THE HOUSING

– INSTALL THE SPRING GUIDE

– PRESSING CONE OF REAR BEARING INTO SHAFT

– INSTALLING BEARING PLATE

– PLACING VALVE PLATE ON END CAP

– INSTALLING END CAP

– INSTALLING CHARGE PUMP

– INSTALLING SHAFT SEAL

– TROUBLESHOOTING THE HYDRAULIC SYSTEM

– TROUBLESHOOTING THE HYDROSTATIC SYSTEM

MECHANICAL DRIVE

– CLUTCH ADJUSTMENT DIESEL ONLY

– CLUTCH REMOVAL

– POWER TRANSFER CHAIN

– TRANSFER CHAINCASE REMOVAL

– CHAINCASE SERVICE

– REDUCTION GEARCASES

– GEARCASE MOUNTING

– GEARCASE REMOVAL

– DISASSEMBLING A CLARK REDUCTION GEARCASE

– REASSEMBLING A CLARK REDUCTION GEARCASE

– DISASSEMBLING A FUNK GEARCASE

– REASSEMBLING A FUNK GEARCASE

– FINAL DRIVE CHAIN ADJUSTMENT

– FINAL DRIVE CHAIN REMOVAL

– AXLE CARRIER REMOVAL

– DISASSEMBLING THE AXLE CARRIER

– REASSEMBLING THE AXLE CARRIER

– AXLE CARRIER REINSTALLATION

– FINAL DRIVE CHAIN REINSTALLATION

– FINAL DRIVE IDLER REPAIR

PERKINS ENGINE SERVICE

– ENGINE REMOVAL

– INTRODUCTION TO ENGINE REPAIR

– UNIFIED THREADS

– ENGINE NUMBER

– ENGINE DESCRIPTION

– LUBRICATING OIL SUMP

– CRANKCASE VENTILATION

– BREATHER ASSEMBLY

– TO REMOVE CYLINDER HEAD

– VALVE REMOVAL

– CLEANING

– VALVE GUIDES

– VALVES AND VALVE SEATS

– HAND GRINDING

– VALVE SEAT INSERTS EXHAUST VALVE

– MILLING OF CYLINDER HEAD

– VALVE SPRINGS

– ROCKER SHAFT ASSEMBLY

– PUSH RODS

– VALVE STEM OIL SEALS

– TO REASSEMBLE CYLINDER HEAD

– CYLINDER HEAD GASKET

– TP REINSTALL CYLINDER HEAD

– TO REMOVE PISTONS AND CONNECTING ROD ASSEMBLIES

– TO REMOVE PISTONS AND RINGS FROM CONNECTING ROADS

– INSPECTION

– TO ASSEMBLE PISTONS TO CONNECTING RODS

– TO INSTALL PISTONS AND CONNECTING RODS TO CYLINDER BORE

– INSTALL NEW PISTONS

– CYLINDER LINERS

– TO RENEW CYLINDER LINERS CAST IRON

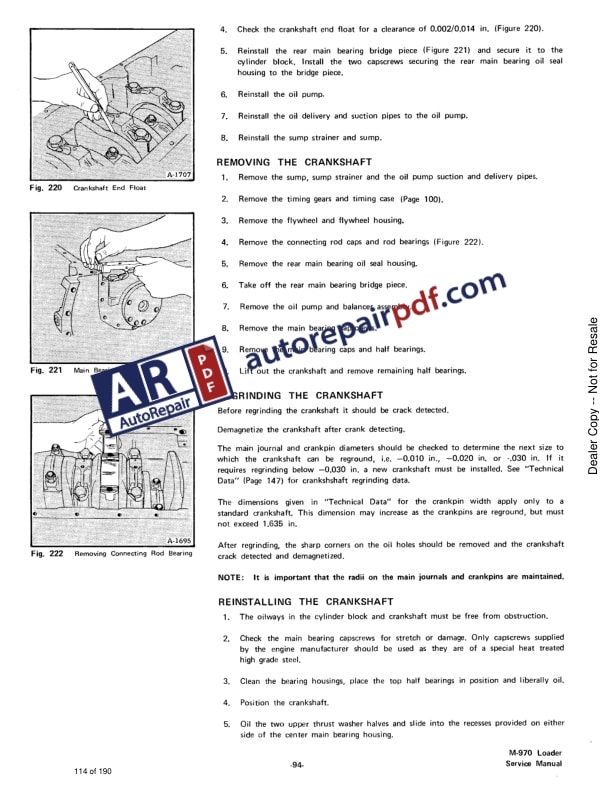

– CRANKSHAFT AND MAIN BEARINGS

– MAIN BEARINGS AND THRUST WASHERS REMOVAL

– INSTALLING MAIN BEARINGS AND THRUST WASHERS

– REMOVING THE CRANSHAFT

– REGRINDING THE CRANKSHAFT

– REINSTALLING THE CRANKSHAFT

– CRANKSHAFT REAR END OIL SEAL

– BALANCE UNIT

– USE OF LOCTITE

– REASSEMBLING THE UNIT

– REMOVING TIMING CASE COVER

– RENEWING THE CRANKSHAFT FRONT OIL SEAL

– REINSTALLING THE TIMING CASE COVER

– CHECKING THE TIMING GEAR BACKLASH

– REMOVING THE IDLER GEAR AND HUB

– REINSTALLING THE TIMING GEAR AND HUB

– REMOVING THE CAMSHAFT GEAR

– REINSTALLING THE CAMSHAFT GEAR

– REMOVING THE FUEL PUMP GEAR

– REINSTALLING THE FUEL PUMP GEAR

– REMOVING THE TIMING CASE

– REINSTALLING THE TIMING CASE

– REMOVING THE CAMSHAFT AND TAPPETS

– REINSTALLING THE CAMSHAFT AND TAPPETS

– CHECKING VALVE TIMING

– LUBRICATION SYSTEM

– DESCRIPTION

– COOLING SYSTEM

– REMOVING AND INSTALLING WATER PUMP

– DISMANTLING THE WATER PUMP

– INSPECTION

– REASSEMBLING THE WATER PUMP

– REMOVING THERMOSTAT

– TESTING THERMOSTAT

– FUEL SYSTEM

– CLEANING HTE PUMP CHAMBER

– REMOVING THE PUMP

– DISMANTLING THE FUEL LIFT PUMP

– INSPECTION OF PARTS

– REMOVING THE FUEL INJECTION PUMP

– REINSTALLING THE FUEL INJECTION PUMP

– FUEL INJECTION PUMP GEAR

– IDLING SPEED SETTING

– PRIMING THE FUEL SYSTEM

– THROTTLE LINKAGE AND FUEL SHUTOFF CONTROL

– COLD WEATHER STARTING AID

– INJECTORS

– FUEL PIPES

– REMOVING THE FLYWHEEL

– RENEWING FLYWHEEL AND RING GEAR

– REINSTALLING THE FLYWHEEL

– REMOVING THE FLYWHEEL HOUSING

– REINSTALLING THE FLYWHEEL HOUSING

– SMOKE DIAGNOSIS CHART

– TROUBLESHOOTING PERKINS

CONTINENTAL ENGINE SECTION

– INFORMATION FOR ORDERING PARTS

– DESCRIPTION OF ENGINE

– LUBRICATION SYSTEM

– OIL PUMP

– OIL FILTER

– COOLING SYSTEM

– CLEANING COOLING SYSTEM

– RADIATOR PRESSURE CAP

– WATER PUMP REMOVAL

– WATER PUMP DISASSEMBLY

– WATER PUMP

– TESTING THERMOSTAT

– COOLANT

– FUEL SYSTEM

– CARBURETOR REMOVAL

– DISASSEMBLY OF THE FUEL BOWL BODY

– CLEANING THE CARBURETOR

– DISASSEMBLY OF THE THROTTLE BODY

– CARBURETOR REINSTALLATION

– FUEL PUMP SERVICE

– IGNITION SYSTEM

– IGNITION COIL

– DISTRIBUTOR

– DISTRIBUTOR MAINTENANCE

– SPARK PLUGS

– GAPPING THE SPARK PLUG

– COLD, NORMAL, HOT SPARK PLUGS

– IGNITION TIMING

– ENGINE REMOVAL

– ENGINE REPAIR AND OVERHAUL

– CYLINDER HEAD

– CYLINDER BLOCK

– VALVE GUIDES

– VALVE SEAT INSERTS

– VALVES

– VALVE SPRINGS

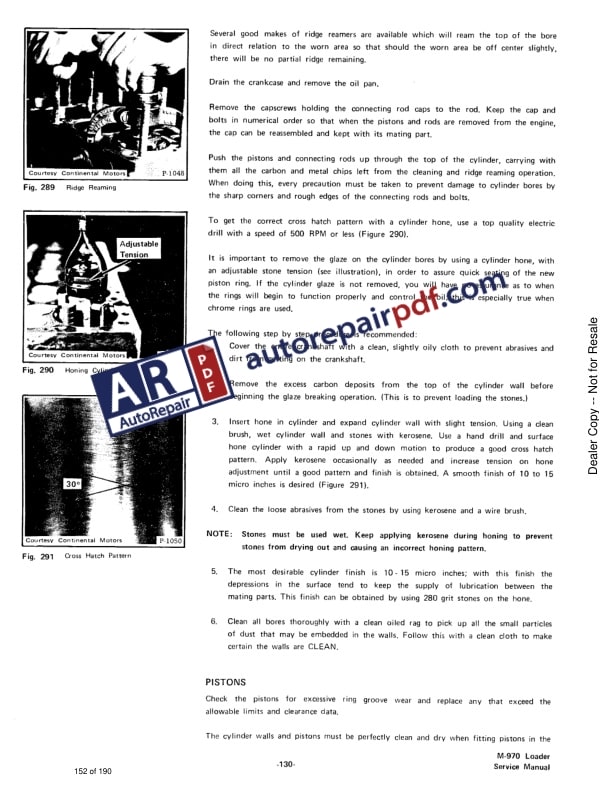

– PREPARING CYLINDER WALLS FOR REGRINDING OR REBORING

– PISTONS

– PISTON PINS

– CONNECTING ROD

– PISTON AND CONNECTING ROD ASSEMBLY

– PISTON RINGS

– RECOMMENDED METHOD OF INSTALLING PISTON RINGS

– CRANKSHAFT AND MAIN BEARINGS

– BEARINGS

– CAMSHAFT

– TAPPETS

– LIMITS AND CLEARANCE

– TIMING GEARS

– CRANKSHAFT END PLAY

– ASSEMBLING OIL SEALS IN FILLER BLOCK AND OIL GUARD

– JUTE TYPE OIL SEALS

– NEOPRENE OIL SEAL

– OIL PUMPS

– FLYWHEEL AND FLYWHEEL HOUSING

– REASSEMBLING ENGINE

– TROUBLESHOOTING THE ENGINE

TECHNICAL DATA, LIMITS AND CLEARANCES

– TECHNICAL DATA PERKINS

– TECHNICAL DATA CONTINENTAL

– LOADER TORQUES SPECIFICATIONS

– TIME REQUIRED FOR SERVICE

– FORMS

– M970 DIESEL LOADER SPECIFICATIONS

– M970 GASOLINE LOADER SPECIFICATIONS

SERVICE BULLETINS

– 7627

SERVICE MANUAL REVISIONS

– 9701

– 9702

Reviews

There are no reviews yet.